‘T’

nuts!

Picture 1: Ends of hex bar retreived from the scrap box in a friends machine shop destined to be thrown away.

Picture 2: Ready to be faced on the metal lathe.

Picture 3: Faced and turned down to fit the top half of the 'T' channel.

Picture 4: Hole drilled (Tap size) in this case 5.5mm for 1/4 UNF Tap.

Picture 5: Bottoming Tap (1/4 UNF) started in lathe for correct 90 degree right angle.

Picture 6: Channel on Milling machine.

Picture 7: Channel on angled table.

Picture 8 & 9: showing where the 'T' bolts go on the angled table.

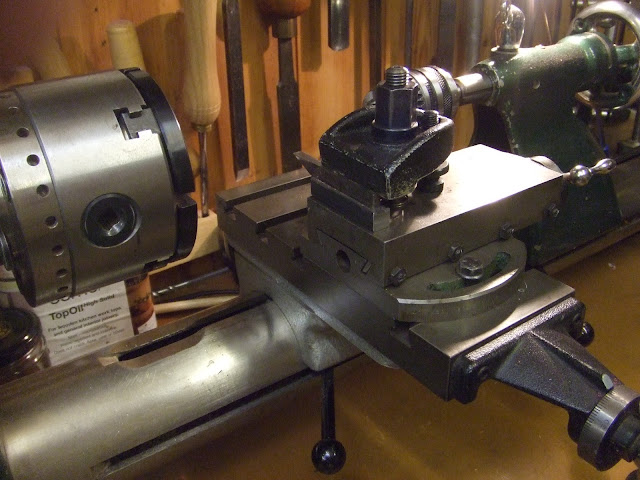

Picture 10: The Myford ML8 wood lathe compound slide.

(All these channels are a different size! and separate 'T' bolts have to be made to fit each channel)

******************************************************

I have been fortunate in making the acquaintance of a very

talented lady who is an ornamental turner; the work she produces is absolutely

incredible. Talking to her the other week I told her of my latest acquisition,

a tilting table for the milling machine in my little workshop. I have been

amazed at the accuracy of this small table for the price I paid, but like

everything these days there is one big draw-back and that is the ‘T’ channels

to anchor it down on the milling bed.

We discussed this problem at

length because all this lady has is a pillar-drill and there was no way she

could utilise one because there is not any ‘T’ nuts available on the market

that would fit the pillar-drill table and also the angle table.

The Photo’s I have taken I think

explains this a little better. (I hope)

I do not understand the logic of

some of the retail outlets today; selling something that is totally useless

because it is not complete. Fortunately I have been able to help her by making

the nuts to fit her tables, and she is now a very happy camper. But I wonder at

how many lost sales there have been in this country all having the same

problem.

Why ‘O’ why are they not

standardised like a Morse-Taper or screw threads making life so much easier.

Anyway, I have had my moan, and

to be perfectly honest I quite enjoy the task of making them, being fortunate

enough to have the equipment to do so.

So if you are thinking of buying

a new piece of shiny equipment for your existing machinery, be careful! Ask

yourself if there are ‘T’ nuts available to anchor it down first before you get

carried away with the glossy pictures advertising its virtues.

Thanks for stopping by, please

call again.

No comments:

Post a Comment